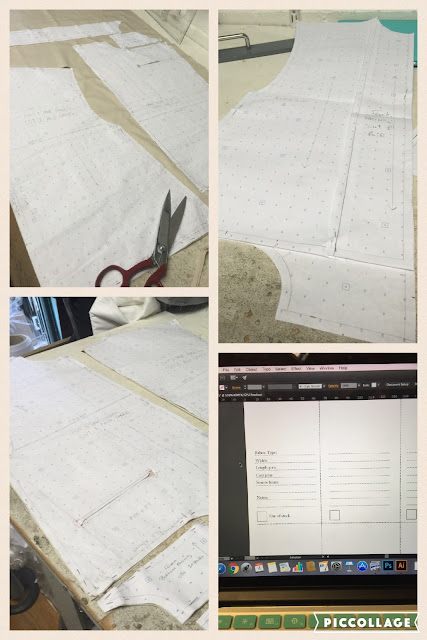

I started off the week by helping Ivor cut out the fabric for one of the many jackets he is currently working on. Once I had finished cutting the fabric I moved on to creating a fabric swatch sheet for us to use for the next time we need to source fabric. The sheet includes details of the price, type of material, fabric width and how many metres needs to be purchased. This makes it a lot clearer for the person who is looking for the fabric to understand and hopefully will speed up the process.

I have also been working on the outer shell of my waistcoat toile, focusing on basting in the canvas and carefully finishing the darts, ad jetted pockets. I decided to use quite a stiff canvas as it will support the tweed, I am quite excited to do this toile as I am using actual canvas this time as apposed to some of the other times where I just used calico as a substitute, there is a big difference when using the real canvas and you can begin to see the waistcoat taking its shape, form and structure. I really enjoy the process of creating a tailored jacket, or waistcoat I especially like basting the material by hand because I feel it is quite relaxing however I am still getting used to using a thimble that is definitely something that doesn't come naturally to me.

Once I added the darts into the waistcoat I started to focus on the jetted pockets. I feel as since I have been working for Ivor jetted pockets have become second nature to me especially using the canvas with them. So I managed to complete the pockets rarely quickly and without any problems or hiccups. The images above show some of the construction processes.

Once I was happy with the pockets I was then able to start adding the front and back together as well as the lining.

As this week is my hand in week I decided to interview Ivor to add to my final report to give more of a personal view of what the industry is like from his perspective. The experience at Nylander Couture has made my interest in the bespoke tailoring

industry stronger, encouraged me to consider a course to learn all there is to know

about tailoring and look into learning more about the business side of things.

Watching Ivor run his own business has inspired me to learn more about financing

a business, sourcing quality materials and the day to day workings of a business in

the fashion industry.